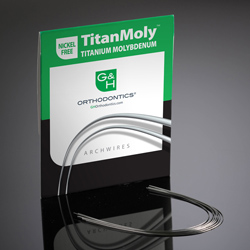

Wires & Accessories - Titanmoly™ Titanium Molybdenum

Supplier: G&H Orthodontics

$61.59

Supplier: G&H Orthodontics

$51.54

Supplier: G&H Orthodontics

$97.13

Supplier: G&H Orthodontics

$51.54

Showing 1 to 10 of 10 (1 Pages)

-80x80.jpg)

-250x250.jpg)

-250x250.jpg)

-250x250.jpg)

-250x250.jpg)